Durafoam™ Closed Cell Sponge Rubber & Plastic Foam

Durafoam™ is our INDUSTRY-LEADING closed cell sponge rubber and plastic foam, and is available as an equivalent to any current or obsolete Rubatex, Ensolite or ANR stock – We ship all over the world.

Durafoam™ is our INDUSTRY-LEADING closed cell sponge rubber and plastic foam, and is available as an equivalent to any current or obsolete Rubatex, Ensolite or ANR stock – We ship all over the world.

Physical Properties

- Outstanding sound absorption

- Excellent shock absorption

- High strength-to-weight ratio

- Superior insulation against heat and cold

- Exceptional Flotation

Available in conductive, non-conductive and fire-retardant versions, Durafoam contains co CFC’s or HCFC’s. It’s also ROHS compliant and 100% recyclable.

Competitive Stock Number Equivalency Charts:

1. Durafoam™ Stocks Comparable to Rubatex® Stocks – View Chart

2. Durafoam™ Stocks Comparable to Ensolite® Stocks – View Chart

3. Durafoam™ Stocks Comparable to ANR Stocks – View Chart

Monmouth Rubber & Plastics.

We make it in America and Ship Worldwide.

Call Toll Free: (888) 362-6888

for Free Samples and Free Tech Support.

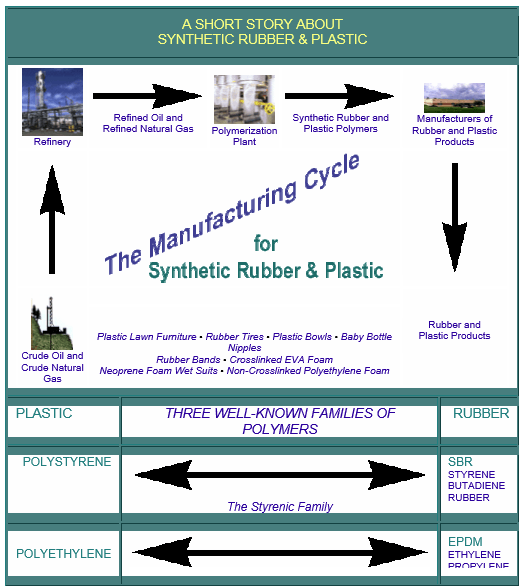

Rubber Library Resource:

NEW! Check it out after you read this page

Durafoam™ is available in some of the following types of rubber:

The Choice of Industry Leaders in a Wide Variety of Markets

- Transportation

- Construction

- Athletic

- Water Sports

- Medical

Sheets of “Closed Cell UL Gaskets” available in our UL Listed Durafoam DK Series

The Durafoam DK Series offers fabricators a one-stop shop for competitively priced materials that meet 80% of all the specifications you require, and offers the fabricator a one-stop shop at competitive pricing for:

- UL 50E – Std safety for enclosures for electrical equipment

- UL 508 – Std for safety industrial control equipment

- UL 157 – Std for safety for gasket and rubber seals

- UL 94 HF1 – Std for safety for test for flammability for plastic materials

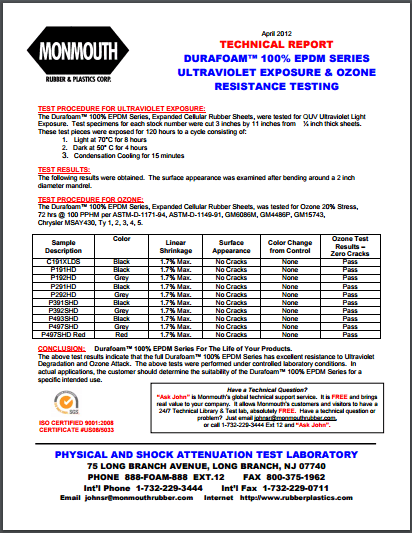

ULTRAVIOLET EXPOSURE & OZONE RESISTANCE TESTING DURAFOAM™ 100% EPDM SERIES

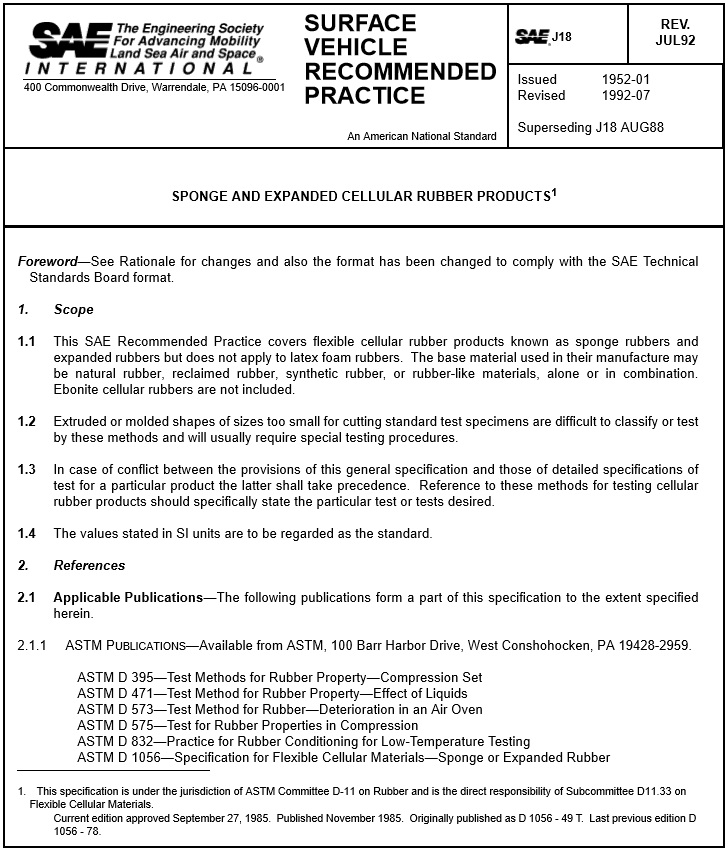

SOCIETY OF AUTOMOTIVE ENGINEERS - SURFACE VEHICLE RECOMMENDED PRACTICE

CLOSED CELL APPLICATIONS ARE DETERMINED BY YOU…

From Concept to Solution: If you can dream it, Monmouth Rubber can make it!

SOME TYPICAL CLOSED CELL APPLICATIONS DURAFOAM IS USED FOR:

Automotive Industry

• AC/Heating Ventilating systems gaskets and seals

• Lighting Gaskets (Interior and Exterior)

• Dash Panel and Steering Column Seals

• Noise, Vibration & Harmonics Pads

Appliances

• Seals and Gaskets, Humidifier Mounting Pads, Sander Pads

• Sound Equipment Padding, Stereo Speaker Vibration Pads Lighting Equipment and Electrical Sign Gaskets (UL)

Construction – read more

• Electrical Box and Receptacle Seals

• Door Seals, Window Seals, Weather Stripping Lighting Fixtures

• Concrete Curing Blankets and Expansion Joint

Control Panels

• Air/Dust/Water Seals (Fire/Security Systems)

Electrical Enclosures

• Air/Dust/Oil/Water Seals (UL recognized for NEMA applications

Heating/Air Industry

• Air/Dust Seals, Gaskets/Weather Stripping

Lighting Industry

• Interior/Exterior, Air/Dust/Water Seals

Medical Industry

• Medical Equipment, Packaging, Pharmaceutical, Surgical

Sports Equipment

• Back Pack Pads, Knee Pads, Boat Cushions, Fishing Rod Holders

Other Applications

• Die Ejection Materials, Weather Stripping

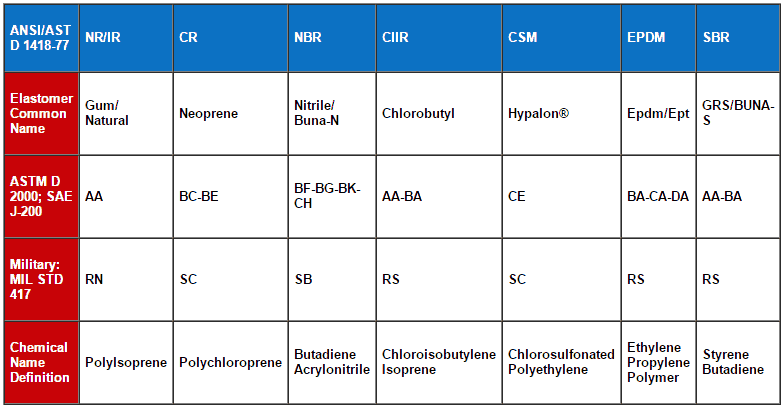

Mobile devices view chart in landscape

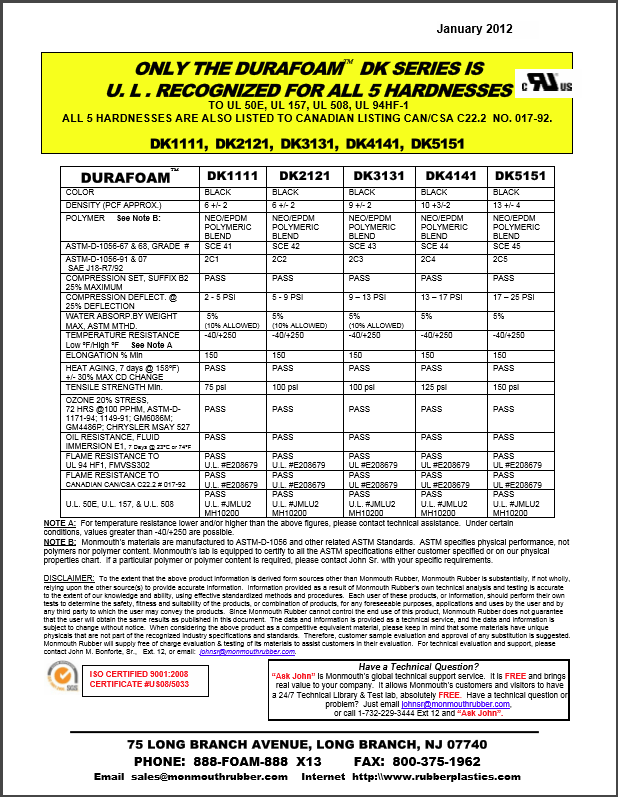

UL GASKETS

Sheets of “Closed Cell UL Gaskets” available in our UL Listed Durafoam DK Series -

UL Listed Closed Cell Sponge Rubber & Plastic Foam.

Only The Durafoam Dk Series Is:

U.L. Recognized for all 5 Hardnesses to UL 50E, UL 157, UL 508, UL 94HF-1

All 5 Hardnesses are also listed To Canadian Listing CAN/CSA C22.2 NO. 017-92.

DK1111, DK2121, DK3131, DK4141, DK5151

UL Listed EPDM/NEOPRENE Closed Cell Rubber Blend, Durafoam™ DK Series (DK111, DK2121, DK3131, DK4141, DK5151)

UL Recognized DURAFOAM DK SERIES CLOSED CELL RUBBER is the only full line of ASTM SCE 41 THROUGH SCE 45 that is recognized to UL 50, UL 157, UL508, UL 94HF-1, and CANADIAN LISTING CAN/CSA C22.2 NO. 017-92

RoHS REACH Prop 65 Berry Certificate Conflict Minerals SDS ISO 9001:2015 Recycled/Sustainability

| DURAFOAM | DK1111 | DK2121 | DK3131 | DK4141 | DK5151 |

| COLOR | BLACK | BLACK | BLACK | BLACK | BLACK |

| DENSITY (PCF APPROX.) | 6 +/- 2 | 6 +/- 2 | 9 +/- 2 | 10 +3/-2 | 13 +/- 4 |

| POLYMER See Note B: | NEO/EPDM POLYMERIC BLEND | NEO/EPDM POLYMERIC BLEND | NEO/EPDM POLYMERIC BLEND | NEO/EPDM POLYMERIC BLEND | NEO/EPDM POLYMERIC BLEND |

| ASTM-D-1056-67 & 68, GRADE # | SCE 41 | SCE 42 | SCE 43 | SCE 44 | SCE 45 |

| ASTM-D-1056-91 & 07 SAE J18-R7/92 | 2C1 | 2C2 | 2C3 | 2C4 | 2C5 |

| COMPRESSION SET, SUFFIX B2 25% MAXIMUM | PASS | PASS | PASS | PASS | PASS |

| COMPRESSION DEFLECT @ 25% DEFLECTION | 2 - 5 PSI | 5 - 9 PSI | 9 – 13 PSI | 13 – 17 PSI | 17 – 25 PSI |

| WATER ABSORP. BY WEIGHT MAX, ASTM MTHD. | 5% (10% ALLOWED) | 5% (10% ALLOWED) | 5% (10% ALLOWED) | 5% | 5% |

| TEMPERATURE RESISTANCE Low ºF/High ºF See Note A | -40/+250 | -40/+250 | -40/+250 | -40/+250 | -40/+250 |

| ELONGATION % Min | 150 | 150 | 150 | 150 | 150 |

| HEAT AGING, 7 days @ 158ºF) +/- 30% MAX CD CHANGE | PASS | PASS | PASS | PASS | PASS |

| TENSILE STRENGTH Min. | 75 psi | 100 psi | 100 psi | 125 psi | 150 psi |

| OZONE 20% STRESS, 72 HRS @100 PPHM, ASTM-D- 1171-94; 1149-91; GM6086M; GM4486P; CHRYSLER MSAY 527 | PASS | PASS | PASS | PASS | PASS |

| OIL RESISTANCE, FLUID IMMERSION E1, 7 Days @ 23ºC or 74ºF | PASS | PASS | PASS | PASS | PASS |

| FLAME RESISTANCE TO UL 94 HF1, FMVSS302 | PASS U.L. #E208679 | PASS U.L. #E208679 | PASS UL #E208679 | PASS UL #E208679 | PASS UL #E208679 |

| FLAME RESISTANCE TO CANADIAN CAN/CSA C22.2 # 017-92 | PASS U.L. #E208679 | PASS U.L. #E208679 | PASS UL #E208679 | PASS UL #E208679 | PASS UL #E208679 |

| U.L. 50E, U.L. 157, & U.L. 508 | PASS U.L. #JMLU2 MH10200 | PASS U.L. #JMLU2 MH10200 | PASS U.L. #JMLU2 MH10200 | PASS U.L. #JMLU2 MH10200 | PASS U.L. #JMLU2 MH10200 |

NOTE A: For temperature resistance lower and/or higher than the above figures, please contact technical assistance. Under certain

conditions, values greater than -40/+250 are possible.

NOTE B: Monmouth’s materials are manufactured to ASTM-D-1056 and other related ASTM Standards. ASTM specifies physical performance, notpolymers nor polymer content. Monmouth’s lab is equipped to certify to all the ASTM specifications either customer specified or on our physical properties chart. If a particular polymer or polymer content is required, please contact John Sr. with your specific requirements.

DISCLAIMER: To the extent that the above product information is derived form sources other than Monmouth Rubber, Monmouth Rubber is substantially, if not wholly, relying upon the other source(s) to provide accurate information. Information provided as a result of Monmouth Rubber’s own technical analysis and testing is accurate to the extent of our knowledge and ability, using effective standardized methods and procedures. Each user of these products, or information, should perform their own tests to determine the safety, fitness and suitability of the products, or combination of products, for any foreseeable purposes, applications and uses by the user and by any third party to which the user may convey the products. Since Monmouth Rubber cannot control the end use of this product, Monmouth Rubber does not guarantee that the user will obtain the same results as published in this document. The data and information is provided as a technical service, and the data and information is subject to change without notice. When considering the above product as a competitive equivalent material, please keep in mind that some materials have unique physicals that are not part of the recognized industry specifications and standards. Therefore, customer sample evaluation and approval of any substitution is suggested.

Monmouth Rubber will supply free of charge evaluation & testing of its materials to assist customers in their evaluation. For technical evaluation and support, please contact John M. Bonforte, Sr., 1-732-229-3444 Ext 112, or email John Sr.

Durafoam DK Series UL Chart [PDF Download]

Have a Technical Question?

“Ask John” is Monmouth’s global technical support service. It is FREE and brings real value to your company. It allows Monmouth’s customers and visitors to have a 24/7 Technical Library & Test lab, absolutely FREE.

Durafoam™ Closed Cell Low Density EPDM PE P4991 TAN

Physical Properties

Request Technical InformationNote: This chart is best viewed in landscape (rotated) on mobile devices.

| PHYSICAL PROPERTIES | DURAFOAM P4991 |

| Polymer | EPDM/PE |

| Color | Tan |

| ASTM-D 1056-67 ASTM-D 1056-14 Suffix Requirements |

RE-42 2A2 |

| 25% Compression Deflection (PSI) | C1 , F2, M, P |

| 50% Compression Set (% max) | 5-8 |

| Density (lb/ft³) | 40 |

| Water Absorption (lb/ft²) | 4-7 |

| Tensile (PSI) | 0.1 max |

| Elongation (%) | 40 min |

| Flammability – FMVSS302 | 225 min |

| Ozone Resistance: Ozone 20% Stress, 72 HRS @ 1 00 PPHM, ASTM-D- 1171-94; 1149-91 ; GM6086M; GM4486P; CHRYSLER MSAY 527 |

Excellent 0 Cracks Pass – – |

DISCLAIMER: To the extent that the above product information is derived form sources other than Monmouth Rubber, Monmouth Rubber is substantially, if not wholly, relying upon the other source(s) to provide accurate information. Information provided as a result of Monmouth Rubber’s own technical analysis and testing is accurate to the extent of our knowledge and ability, using effective standardized methods and procedures. Each user of these products, or information, should perform their own tests to determine the safety, fitness and suitability of the products, or combination of products, for any foreseeable purposes, applications and uses by the user and by any third party to which the user may convey the products. Since Monmouth Rubber cannot control the end use of this product, Monmouth Rubber does not guarantee that the user will obtain the same results as published in this document. The data and information is provided as a technical service, and the data and information is subject to change without notice. When considering the above product as a competitive equivalent material, please keep in mind that some materials have unique physicals that are not part of the recognized industry specifications and standards. Therefore, customer sample evaluation and approval of any substitution is suggested. Monmouth Rubber will supply free of charge evaluation & testing of its materials to assist customers in their evaluation.

Monmouth Rubber will supply free of charge evaluation & testing of its materials to assist customers in their evaluation. For technical evaluation and support, please contact John M. Bonforte, Sr., 1-732-229-3444 Ext 112, or Email John Sr..

Durafoam™ Closed Cell Low Density EPDM PE P4991 TAN [PDF Download] Have a Technical Question?

“Ask John” is Monmouth’s global technical support service. It is FREE and brings real value to your company. It allows Monmouth’s customers and visitors to have a 24/7 Technical Library & Test lab, absolutely FREE.

Monmouth Has Been Supplying Durafoam and Bondaflex Materials to the Construction Industry for more than 50 years.

DURAFOAM C121A

Neoprene/Polymeric Blend Sponge

ASTM-D-1056-07 2A1

DURAFOAM DK5151 HD

Neoprene/EPDM/Polymeric Blend

ASTM-D-1056-07 2C5

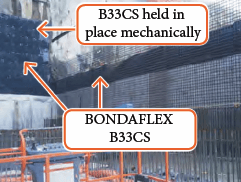

BONDAFLEX B33CS

Sponge Rubber Expansion Joint Filler

ASTM-D-1752-04 TYPE 1,

HH-F-341, TYPE II, CLASS A,

AASHTO M 153, TYPE I FAA

P-610-2.7, CRD-C 509 TYPE I

DURAFOAM DK1111 LD

Neoprene/EPDM/Polymeric Blend

UL Listed – Self Extinguishing

ASTM-D-1056-07 2C1

DURAFOAM XP20

Cross Linked Polyethylene

and EVA Foam

ASTM-D-3575-05

DURAFLEX MR60CS

Solid Rubber Bearing Pads

AASHTO – ASTM-D-2000 –

COMMERCIAL

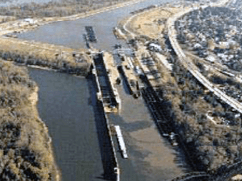

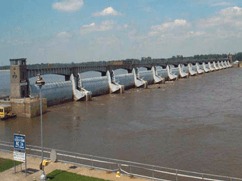

Just four examples of how Monmouth’s materials (Bondaflex B33CS & Durafoam C121A) helped guarantee the success of the project:

Hoover Dam

Bypass Project

McAlpine Lock Project

Red River Water Control

Project

Durafoam DK Series Closed Cell Rubber was a savior for church foundation.

St. Patrick’s Cathedral

Restoration Project

Five Year Restoration Project

Necessary for its Survival

TECHNICAL DATA SHEETS

Neoprene Explained

Neoprene was the world’s first fully commercial synthetic elastomer

EVA Explained

Ethylene-vinyl acetate (EVA) is the copolymer of ethylene and vinyl acetate.

ASTM D 1056 explained

Standard Specification For Flexible Cellular Materials

UL Gasket Materials explained

Underwriters Laboratories has a set of industry standards that it uses to test electronic components, including gaskets.

The Shelf Life of Rubber explained

With the above in mind, it is important not to confuse Shelf Life with Service Life.

CONTACT US

INT’L PHONE:

(732) 229-3444

TOLL FREE:

(888) 362-6888

FAX:

(732) 229-0711

EMAIL:

sales@monmouthrubber.com

Our Team

Team Monmouth's commitment is to bring ongoing value to our customers. We constantly strive to improve products and services that meet your needs and exceed your expectations. Please select one of our team members below to discuss how we can help you!

Cut It. Coat It. Form it. It will do just about anything you want it to do.

Whether you’re looking for open cell sponge rubber, solid sheeting or closed cell plastic foam, you can count on Monmouth Rubber & Plastics to deliver the materials you want.

DURAFOAM™

Closed Cell Sponge Rubber and Plastic Foam

DURAFLEX™

Solid Rubber

and Plastic Sheeting

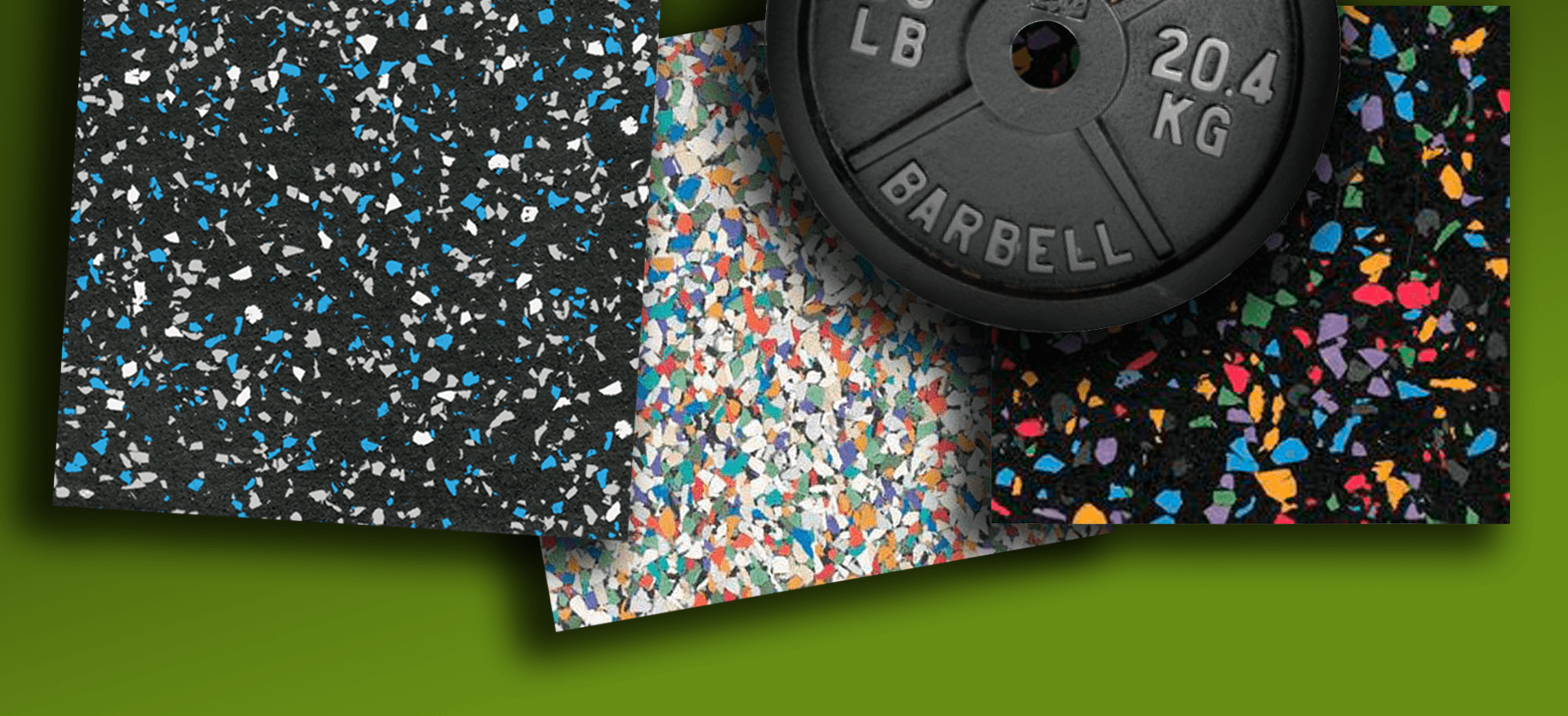

BONDAFLEX™

Recyled Composites of Rubber and Plastic

BUNS

Closed Cell Sponge Rubber & Plastic Foam

SHEETS

Closed Cell, Open Cell & Solid Rubber

ROLLS

Closed Cell Sponge Rubber and Plastic

FOAM TAPE

Closed Cell Tape, Strip & Pressure Sensitive

NEW! Equivalents to any current or obsolete Rubatex, Ensolite or ANR stock Competitive Stock Number Equivalency Charts:

1. Durafoam™ Stocks Comparable to Rubatex® Stocks - View Chart

2. Durafoam™ Stocks Comparable to Ensolite® Stocks - View Chart

REQUEST SAMPLES Rubber & plastic foam materials Read more>

FREE TECH SUPPORT Global support and Solutions Read more>

TRASH FOR CASH Recycling Program Read more>

"ASK JOHN" - Q&A With John Bonforte, Sr. Read more>

IN THE NEWS Monmouth Rubber & Plastics Read more>

TECHNICAL LITERATURE Articles, Releases & Data Sheets Read more>

CONVERSION TOOLS Variety of different measurements. Read more>

PRICING & SALES SUPPORT Call or write us Read more>

- REQUEST SAMPLES Rubber & plastic foam materialsRead more>

- FREE TECH SUPPORT Global support and Solutions Read more>

- TRASH FOR CASH Recycling Program Read more>

- "ASK JOHN" - Q&A With John Bonforte, Sr. Read more>

- IN THE NEWS Monmouth Rubber & Plastics Read more>

- TECHNICAL LITERATUREArticles, Releases & Data Sheets Read more>

- CONVERSION TOOLS Variety of different measurements.Read more>

- PRICING & SALES SUPPORTCall or write us Read more>

EXPLAINED

Neoprene explained,

what is it?

Neoprene was originally used as an oil resistant replacement for natural rubber.

by Monmouth Rubber & Plastics

EVA explained,

what is it?

Broadly speaking, there are three different types of EVA copolymer.

by Monmouth Rubber & Plastics

ASTM D 1056

explained

American Society For Testing Materials D1056 (ASTM D1056)

by Monmouth Rubber & Plastics

UL Recognized Gasket Materials

Underwriters Laboratories - UL Gaskets are tested using the Standard for Safety of Gaskets and Seals.

by Monmouth Rubber & Plastics

The Shelf Life

of Rubber

Shelf life of rubber is a simple question with a complex answer.

by Monmouth Rubber & Plastics

JUST ASK JOHN

FREE TECH SUPPORT

John Bonforte Sr.

Free support whether we make your product or not.

Sign Up To Receive Free

News You Can Use

on Closed Cell Sponge Rubber & Plastic Foam Materials and New Developments. By John Bonforte, Sr.