Recycled Rubber & Plastic Foam Manufacturer

Monmouth Rubber & PlasticsWe make it in America and Ship Worldwide.

Call Toll Free: (888) 362-6888

for Free Samples and Tech Support.

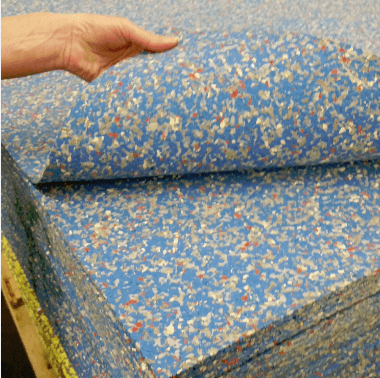

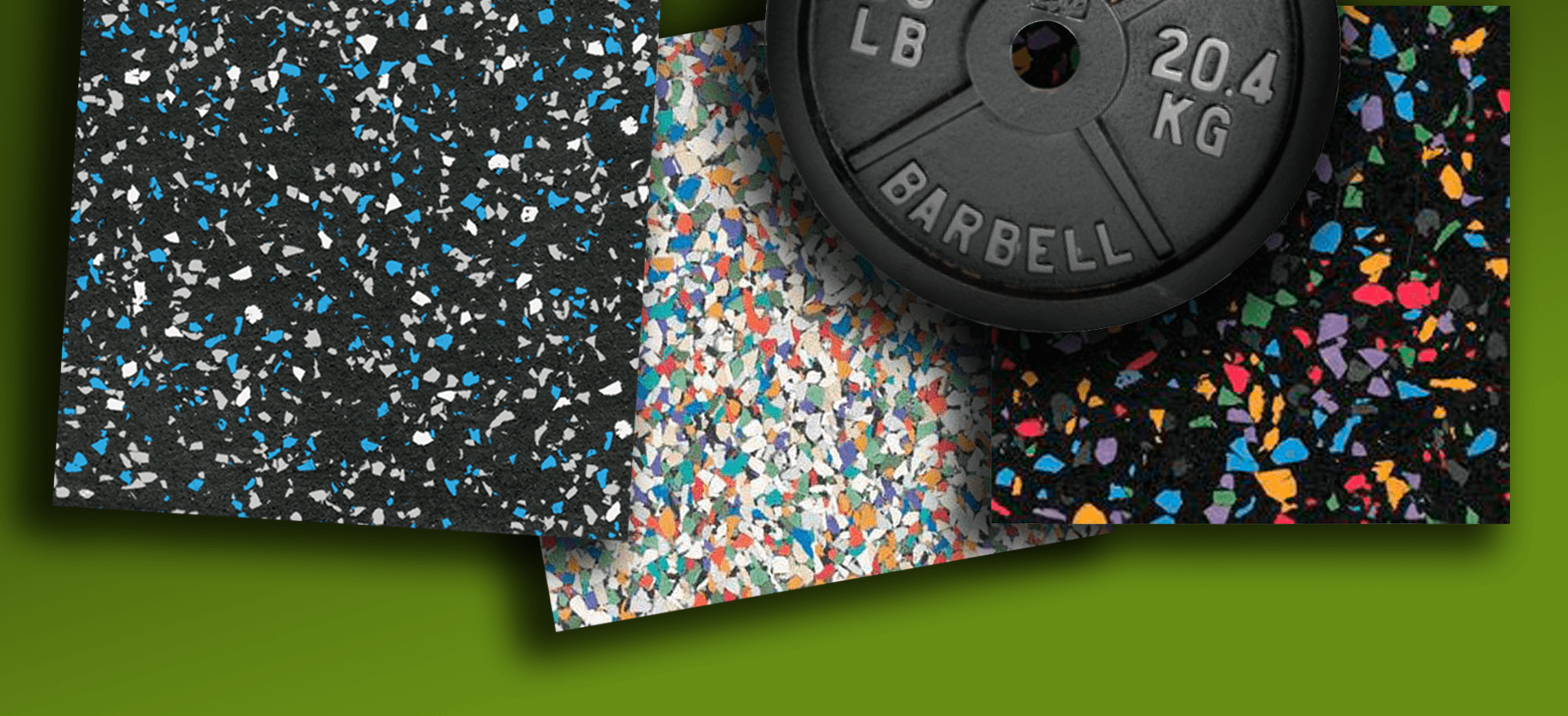

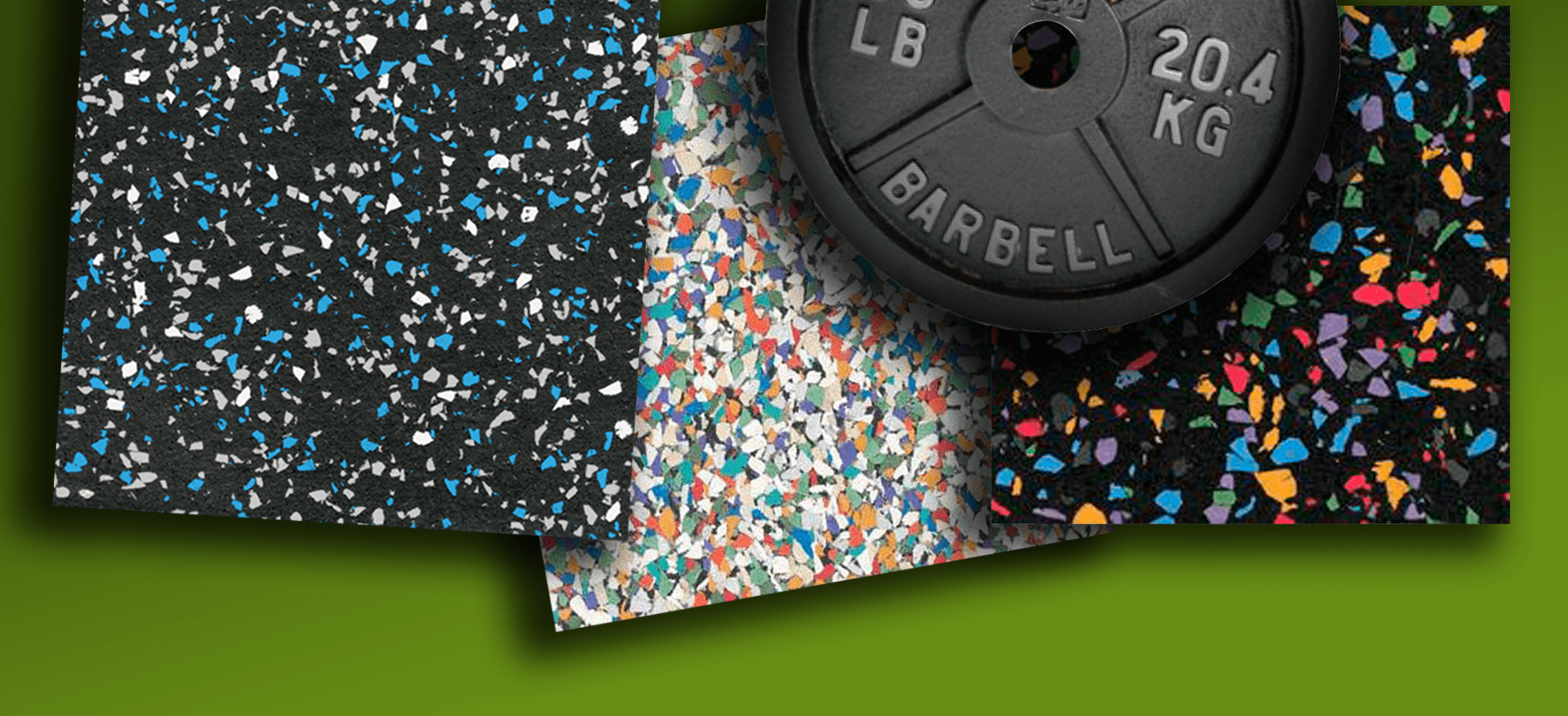

Bondaflex™ is our INDUSTRY-LEADING Controlled Particle Size Composites of Recycled Rubber & Plastic Material available in cellular or solid form.

Our recycled rubber and plastic composites show up in the most diverse products.

Our recycled rubber and plastic composites show up in the most diverse products.

NEW! Check it out after you read this page

Recycled rubber has found its way into every aspect of everyday life.

Dam Gaskets

Drink Coasters

Rubber Flooring

Running Track Surfaces

Factory Mats

And many other Unlimited Applications

Many customers are attracted by Bondaflex’s ability to offer high density at a cost-effective price.

Trusted by Manufacturers Around the World

Manufacturers across the globe trust our Bondaflex™ recycled rubber as an integral component of their products for:

- Econmomy

- Reliability

- Product Innovation

- Preservation of Planet Earth

As other manufacturers are just entering the recycled rubber field, Monmouth Rubber stands proud of our 20+ years of commitment as responsible environmental stewards.

Guarantee

We guarantee that our Long Branch, N.J. facility will accept back 100% of the rubber and plastics material it supplies, including skids, banding wire, stretch wrap and the recycled rubber we make and sell. Over 98% of all waste we generate is recycled.

While we generate a significant portion of the recycled rubber and plastics materials used in the Bondaflex™ process, we also have developed strong relationships with scrap generators who regularly augment our steady supply of recycled materials. We are the only supplier of recycled cellular rubber material that is vertically integrated back to the manufacture of prime cellular materials.

A successful recycling program that serves customers’ needs

on a long term basis requires at least four key elements.

1. A RELIABLE AND CONSISTENT STREAM OF RECYCLABLE MATERIAL

Monmouth’s Strengths: Monmouth generates a significant portion of the recycled rubber materials used in the Bondaflex™ process. A steady supply of materials is augmented by relationships with generators of scrap that go back 50+ years. Monmouth is the only supplier of recycled cellular materials that is vertically integrated back to the manufacturer of prime cellular materials. As a result, Monmouth is able to manufacture rubber and plastics materials for its Bondaflex™ process to augment the supply stream when necessary by using its polymer manufacturing department.

2. STATE-OF-THE-ART RECYCLING EQUIPMENT THAT IS ENERGY EFFICIENT

Monmouth’s Strengths: Monmouth has state-of-the-art equipment for size reduction, size sorting, mixing and curing of our Bondaflex™ product line. All key machines in the recycled process have backup alternatives to ensure that machine downtime does not affect material supply to our customers. Bondaflex™ is highly eco-efficient which means that significantly less energy and raw material are needed to produce our recycled Bondaflex™ rubber products as opposed to the equivalent prime material products.

3. MACHINERY TO PROPERLY SKIVE THE RECYCLED BUNS TO THICKNESS SPECIFIED BY CUSTOMER REQUIREMENTS

Monmouth has state-of-the-art machinery capable of producing materials that will meet your unique specifications. We work in partnership with OEMs, gasket cutters, fabricators, and resellers worldwide.

4. IN-DEPTH QUALITY CONTROL SUPPORT OF BONDAFLEX™ PRODUCTS

Monmouth Rubber has a complete product testing laboratory on site. As part of our quality control and customer support, some of the tests we perform in our laboratory are:

- Compression Deflection

- Tensile Compression

- Set Elongation

- Creep

- UL Burn

- Die C Tear

- Water Absorption

- Fluid Immersion

- Shock Attenuation

- Oven Aging

- Low Temperature Flex

Our product testing and development laboratory has proven to be a valuable asset to our customers. It continues to bring real value to their company and their selling efforts. Our customers realize value, not only in a consistent and quality product, but in the technical support required to develop new products for their customers.

Bondaflex™ Saves Over 20 Million Pounds of the Earth’s Resources.

For the past 20 years, the Bondaflex™ process has eliminated the need for over 20 million pounds of organic industrial production in the form of oil and natural gas, as well as a multitude of chemicals used in the rubber industry.

Global Warming

With its Bondaflex™ process Monmouth has been doing its part to lower greenhouse gases for over 20 years. Industry has continued to increase its participation as responsible environmental stewards of the earth’s environment. Government regulations and industrial requirements will continue to drive new and improved ways of recycling the waste stream on the planet. Monmouth’s commitment to continuous improvement of the environmental impact that industry has on the planet is second to none. Monmouth’s Bondaflex™ process is eco-efficient.

“0” EMISSIONS FOR OUR PLANET:

The MONMOUTH GUARANTEE

Monmouth guarantees that it will accept back at its Long Branch, N.J. facility, 100% of the material that it supplies. This includes skids, banding wire, stretch wrap, as well as the cellular and solid material that Monmouth makes and sells.

Neoprene Explained

Neoprene was the world’s first fully commercial synthetic elastomer

EVA Explained

Ethylene-vinyl acetate (EVA) is the copolymer of ethylene and vinyl acetate.

ASTM D 1056 explained

Standard Specification For Flexible Cellular Materials

UL Gasket Materials explained

Underwriters Laboratories has a set of industry standards that it uses to test electronic components, including gaskets.

The Shelf Life of Rubber explained

With the above in mind, it is important not to confuse Shelf Life with Service Life.

CONTACT US

INT’L PHONE:

(732) 229-3444

TOLL FREE:

(888) 362-6888

FAX:

(732) 229-0711

EMAIL:

sales@monmouthrubber.com

Our Team

Team Monmouth's commitment is to bring ongoing value to our customers. We constantly strive to improve products and services that meet your needs and exceed your expectations. Please select one of our team members below to discuss how we can help you!

Cut It. Coat It. Form it. It will do just about anything you want it to do.

Whether you’re looking for open cell sponge rubber, solid sheeting or closed cell plastic foam, you can count on Monmouth Rubber & Plastics to deliver the materials you want.

DURAFOAM™

Closed Cell Sponge Rubber and Plastic Foam

DURAFLEX™

Solid Rubber

and Plastic Sheeting

BONDAFLEX™

Recyled Composites of Rubber and Plastic

BUNS

Closed Cell Sponge Rubber & Plastic Foam

SHEETS

Closed Cell, Open Cell & Solid Rubber

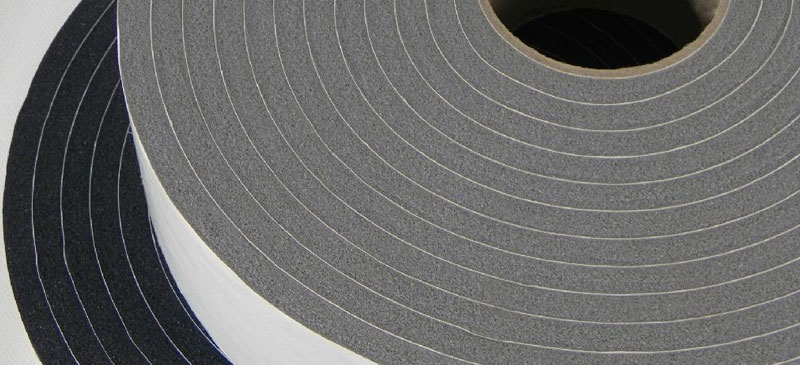

ROLLS

Closed Cell Sponge Rubber and Plastic

FOAM TAPE

Closed Cell Tape, Strip & Pressure Sensitive

NEW! Equivalents to any current or obsolete Rubatex, Ensolite or ANR stock Competitive Stock Number Equivalency Charts:

1. Durafoam™ Stocks Comparable to Rubatex® Stocks - View Chart

2. Durafoam™ Stocks Comparable to Ensolite® Stocks - View Chart

REQUEST SAMPLES Rubber & plastic foam materials Read more>

FREE TECH SUPPORT Global support and Solutions Read more>

TRASH FOR CASH Recycling Program Read more>

"ASK JOHN" - Q&A With John Bonforte, Sr. Read more>

IN THE NEWS Monmouth Rubber & Plastics Read more>

TECHNICAL LITERATURE Articles, Releases & Data Sheets Read more>

CONVERSION TOOLS Variety of different measurements. Read more>

PRICING & SALES SUPPORT Call or write us Read more>

- REQUEST SAMPLES Rubber & plastic foam materialsRead more>

- FREE TECH SUPPORT Global support and Solutions Read more>

- TRASH FOR CASH Recycling Program Read more>

- "ASK JOHN" - Q&A With John Bonforte, Sr. Read more>

- IN THE NEWS Monmouth Rubber & Plastics Read more>

- TECHNICAL LITERATUREArticles, Releases & Data Sheets Read more>

- CONVERSION TOOLS Variety of different measurements.Read more>

- PRICING & SALES SUPPORTCall or write us Read more>

EXPLAINED

Neoprene explained,

what is it?

Neoprene was originally used as an oil resistant replacement for natural rubber.

by Monmouth Rubber & Plastics

EVA explained,

what is it?

Broadly speaking, there are three different types of EVA copolymer.

by Monmouth Rubber & Plastics

ASTM D 1056

explained

American Society For Testing Materials D1056 (ASTM D1056)

by Monmouth Rubber & Plastics

UL Recognized Gasket Materials

Underwriters Laboratories - UL Gaskets are tested using the Standard for Safety of Gaskets and Seals.

by Monmouth Rubber & Plastics

The Shelf Life

of Rubber

Shelf life of rubber is a simple question with a complex answer.

by Monmouth Rubber & Plastics

JUST ASK JOHN

FREE TECH SUPPORT

John Bonforte Sr.

Free support whether we make your product or not.

Sign Up To Receive Free

News You Can Use

on Closed Cell Sponge Rubber & Plastic Foam Materials and New Developments. By John Bonforte, Sr.