QUESTION:

What is recycled closed cell rubber & plastic foam?

ANSWER:

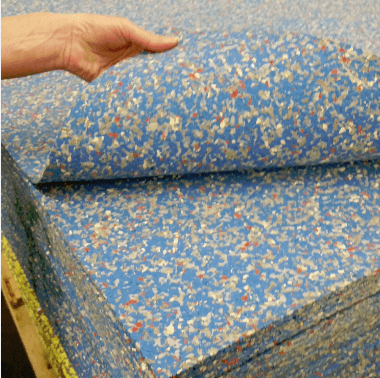

Recycled rubber & plastic foam is a product made from waste pieces from the prime manufacturing process of closed cell sponge rubber and plastic foam. The off fall (scrap) materials from the prime manufacturing process are collected. They are put through a size reduction process to produce ground particles of a controlled size. These ground particles are put into a mixer with binder liquids, blended and put into a high pressure steel mold for forming. The cured recycled bun is then split (skived) in to specified thicknesses based on customer requirements.

Recycled rubber & plastic foam is a product made from waste pieces from the prime manufacturing process of closed cell sponge rubber and plastic foam. The off fall (scrap) materials from the prime manufacturing process are collected. They are put through a size reduction process to produce ground particles of a controlled size. These ground particles are put into a mixer with binder liquids, blended and put into a high pressure steel mold for forming. The cured recycled bun is then split (skived) in to specified thicknesses based on customer requirements.

Monmouth Rubber’s recycled sponge rubber and plastic foam is Bondaflex, it is supplied worldwide for a variety of applications where high density at an economical price is required. The Bondaflex process contributes every day to helping to save the planet. Monmouth Rubber recycles 98% of all materials produced and used at its manufacturing site in Long Branch NJ.

TECHNICAL REPORT: Bondaflex Saves Over 27 Million Pounds Of The Earth’s Resources