The Versatility of Nitrile Butadiene Rubber

Nitrile Butadiene Rubber – General Information

Nitrile Butadiene Rubber Properties

NBR is a copolymer made from butadiene and acrylonitrile. It is used in technical rubber products that need to be resistant to mineral oils, organic fats and oils, and service fluids and greases in automotive applications and machinery. Closed Cell Nitrile (Buna-N) Sponge Rubber can handle temperatures ranging from -40°F to +200°F and traps nitrogen gas in its structure better than most other rubbers, making it ideal for closed cell sponge applications. In addition to oil resistance and temperature range, NBR has a number of properties that set it apart from other rubbers:

- It demonstrates good compression set and compression stress relaxation properties

- It offers resistance to abrasion and wear

- It has low gas permeability

- Nitrile rubber is also resistant to aliphatic hydrocarbons.

- It is less resistant to ozone, aromatic hydrocarbons, ketones, esters and aldehydes.

- It has high resilience and high wear resistance but only moderate strength.

- It has good weather resistance

Applications of Nitrile Butadiene Rubber

Nitrile rubber is extremely versatile. The ability to change the characteristics of nitrile Buna-N rubber by simply altering the amount of acrylonitrile allows manufacturers to produce custom NBR products.It can be heat resistant, abrasion resistant, harder to break, or more elastic. For example, certain fast-curing NBR rubbers retain the polymer’s well-known extreme oil resistance while being engineered to optimize molding applications: in this case to limit mold fouling. The resulting NBR products are also suitable for food and potable water applications and for molded rubber parts such as seals, hoses, and membranes. A Google search on this topic reveals that this is a highly specialized field requiring years of experience to understand which polymers like to chemically “hold hands” and which do not.

Uses of Nitrile Butadiene Rubber

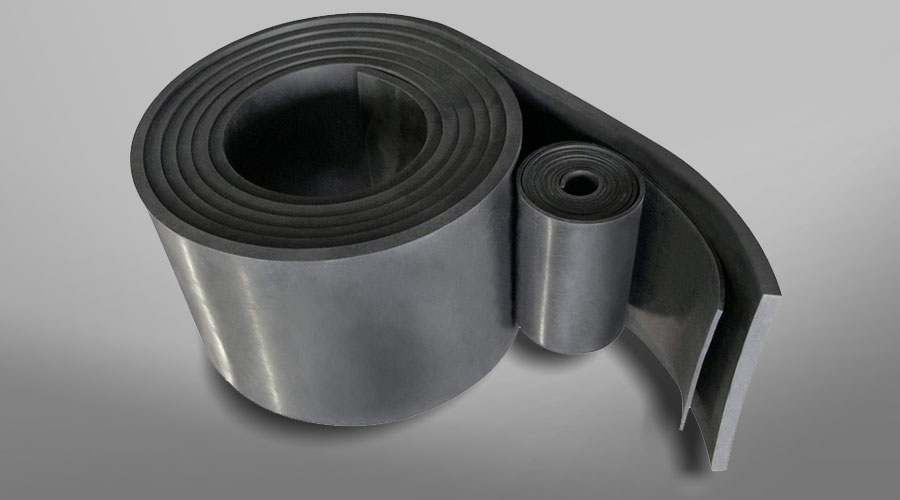

Because of its resilience, synthetic NBR rubber is the perfect material for disposable lab, cleaning, and examination gloves.The same material is used for rubberized fabrics, roll covers, sheets, conveyor and transmission belts, and shoe soles. Many military rubber specifications for fuel and oil resistant O-rings require nitrile based compounds and it can be found in unexpected places like the rubber matting under the carpet at the golf driving range. Other places you can find NBR include:

- Hydraulic hoses

- O-Rings

- Conveyor belting

- Graphic arts

- Oil field packers

- Seals for all kinds of plumbing and appliance applications

- Injection or transfer molded products

- Extruded hose or tubing

- Oil resistant floor mats

- Closed cell sponge articles

- Conveyor and processing belts

- Folder-gluer belts

- Machine tapes

- Power transmission belts

Limitations of Nitrile Butadiene Rubber

Nitrile has poor resistance to ketones, chlorinated hydrocarbons, and nitro hydrocarbons. It does not have good ozone, oxygen or sunlight resistance without the addition of special additives. To obtain good resistance to low temperature, it is often necessary to sacrifice some high-temperature resistance. Articles made from NBR should not be stored near electric motors or other ozone generating equipment. While nitrile rubber is more resistant than natural rubber to oils and acids, it has inferior strength and flexibility. However, items like Nitrile gloves are three times more puncture-resistant than natural rubber gloves.

Conclusion

Because of Nitrile Butadiene Rubber’s compatibility with most environments and relatively low cost when compared to other rubber materials, it is the one of the most commonly used rubber in many products. The possibilities are so great and variable that Buna-N rubber has been an industry standard for decades and will continue to remain a standard for many more.

Nitrile Butadiene Rubber Helpline – Free Technical Support.

If you have any questions about the versatility of Nitrile Butadiene Rubber please contact:

John Bonforte Sr., Technical Support, Nitrile Butadiene Rubber at:

USA Toll free: (800) 375-1960

International: +1 732-229-3444.