Monmouth Rubber & Plastics Corp. has been a leader in the innovation and technology of cellular polymeric materials for over 54 years.

As a recognized leader and innovator of proprietary closed cell cross linking technology and polymer blend technology, Monmouth was retained to do product development and improvement by a variety of companies. Some of these companies, in chronological order, are:

B.F. Goodrich, Sponge Products Div. – Shelton, CT

Neoprene/Vinyl Nitrile Blends

Uniroyal Chemical, Ensolite Div. – Mishawaka, IN

IV-1 IV-5 Series – Neoprene/Vinyl Nitrile Blends – Ensofoam Crosslinked EVA Blends

Plymouth Rubber, Plymouth, MA

Crosslinked Low Density EVA Blends

Sentinel Products Corp. – Hyannis, MA

Polyolefin Blends, all types including Metallocene Resin Crosslinked Foam

Monmouth Rubber & Plastics Corp.’s in-house technology timeline is as follows:

1968 – Monmouth develops and perfects the Durafoam™ multi-step process for the curing and blowing of low-density closed cell materials. Prior to 1968, most materials were cured with the one step or jump-blow process which resulted in densities no lower than 12 pounds per cubic foot. By using a controlled multi-step-cure blow process, Monmouth was able to crosslink and blow materials in densities down to 2 pounds per cubic foot. Monmouth has made significant improvements to this Durafoam™ multi-step process over the years as polymers, products and customer needs have changed.

1969 – Monmouth develops for B.F. Goodrich, Shelton CT, a low density, Vinyl/Nitrile/Neoprene blend for industrial and automotive markets. Monmouth’s proprietary technology in hydrocarbon polymer blending has been the keystone in its technology firsts. The product line developed for B.F. Goodrich in 1969 is the forerunner of the Vinyl/Nitrile/Neoprene blends produced today by Rubatex®, Uniroyal Ensolite and Halstead.

1971 – Monmouth develops the first commercial, low density, Neoprene/SBR blend for the industrial and automotive markets. Listed under ASTM-D-1056, SCE41 through SCE45, Monmouth produced and sold commercial blends of its Durafoam™ C121A series in densities as low as 3.5 pounds per cubic foot.

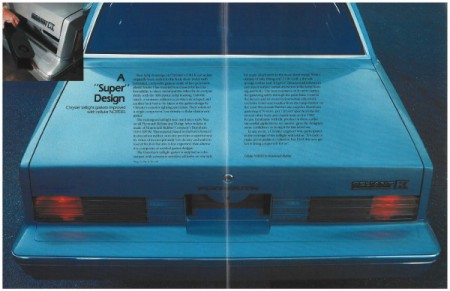

1974 – Monmouth commercializes the world’s first 100% EPDM, low density, closed cell sponge. Proprietary Durafoam™ technology allowed Monmouth to produce the C191XLDS in densities as low as to 2.0 pounds per cubic foot. One outstanding, commercially successful application for this technology was as a sealing gasket for all Chrysler tail lamps. Durafoam™ C191XLDS was used exclusively during the 1980’s in all Chrysler vehicles. Monmouth is currently listed as an approved source under Chrysler MSAY 430.

1977 – Monmouth provides some of the initial EVA Polyethylene crosslinked foam technology and developmental work for the Ensolite Division of Uniroyal. The product was ultimately marketed by Uniroyal under the trade name “Ensofoam”. This developmental work included pilot plant production at our Long Branch facility as well as product development.

1986 – Monmouth introduces its Bondaflex™ line of recycled cellular and solid rubber and plastic materials. Monmouth’s technology centers around its proprietary process for controlled particle size distribution of similar and dissimilar materials. Since 1998, the Bondaflex™ process has resulted in Monmouth being able to recycle in-house 98% of all the materials it manufactures.

The Bondaflex™ process also allows Monmouth to guarantee to its customers that Monmouth will accept back at its Long Branch facility 100% of the material that Monmouth supplies. This includes skids, banding wire, stretch wrap, as well as the cellular and solid material that Monmouth makes and sells. Monmouth knows of no other manufacturer that offers such a guarantee.

August 1996 – Monmouth commercializes its Durafoam™ DK series of Kinetically Grafted Blends. KGB blend technology allows dissimilar polymers (those that do not blend well mechanically) to blend as a result of a chemical bond that develops through proprietary KGB technology. The DK benefit to the customer is a blend product with superior performance and value as opposed to more expensive, homogenous polymers. The DK series of closed cell Neoprene/EPDM blends covers the five hardness ranges of ASTM and have UL listing for flame resistance and gasketing applications.

January 1998 – Monmouth is the first to introduce a 54″ and 60″ wide pressed cured bun in a neoprene blend. The Durafoam™ process results in a press cured bun having an exceptionally large size, a tight cell structure, and superior physical properties as compared to a continuously cured roll by the open air process.

The above technology events allow Monmouth to offer to its customers the following commitment:

“To become and remain the highest quality producer of cellular rubber and plastic buns in the world”.

Other Monmouth products include:

AIRAFLEX™ – Open Cell Sponge Rubber & Plastic Foam

DURAFLEX™ – Solid Rubber & Plastic Sheeting

The Monmouth family of materials has performed well for over 40 years for sound absorption, shock absorption, conductive, non-conductive, fire retardant, high strength to weight ratio, hot and cold insulation, and floatation.

The Monmouth family of materials is made from Neoprene, Natural Rubber, SBR, Butyl, Butadiene, Nitrile, EPDM, ECH, Polystyrene, Polyethylene, Polypropylene, EVA, EMA, Mettalocene Resin, PVC, Polyurethane, and Proprietary Blends of the above.

The Monmouth family of materials is offered in Buns, Sheets, Rolls, Stripping, with and without pressure sensitive adhesive, and specialty laminations.

The Monmouth family of materials is used in the automotive, athletic, shoe, construction, leisure products, and miscellaneous industrial products industries. Monmouth is a global supplier with distribution points in North America, South America, Europe and Asia.

The Monmouth family of materials is sold through Gasket Cutters, Fabricators, and Resellers Worldwide.

Free Technical Support

Monmouth Rubber & Plastics has a comprehensive state-of-the-art physical testing laboratory, including shock attenuation testing equipment. Monmouth is equipped to test and certify to a multitude of industry and government specifications. Some of these specifications are: ASTM-D-1056, SAE J18, MSAY 430, GM6086M, Mil-R-6130, Mil-C-3133, Mil-R-6855, Mil-G-1149, Delphi SD2-207 Sec. 6.1. Product development, product testing, product evaluation, and product sampling are offered by Monmouth as part of its technical support program.

In 1974, Monmouth commercialized the world’s first 100% EPDM, low density,closed cell sponge. Proprietary Durafoam technology allowed Monmouth to produce C191XLDS in densities as low as to 2.0 pounds per cubic foot. One outstanding, commercially successful application for this technology was as a sealing gasket for all Chrysler tail light lamps. In 1979, Monmouth was successful in having

In 1974, Monmouth commercialized the world’s first 100% EPDM, low density,closed cell sponge. Proprietary Durafoam technology allowed Monmouth to produce C191XLDS in densities as low as to 2.0 pounds per cubic foot. One outstanding, commercially successful application for this technology was as a sealing gasket for all Chrysler tail light lamps. In 1979, Monmouth was successful in having